Material

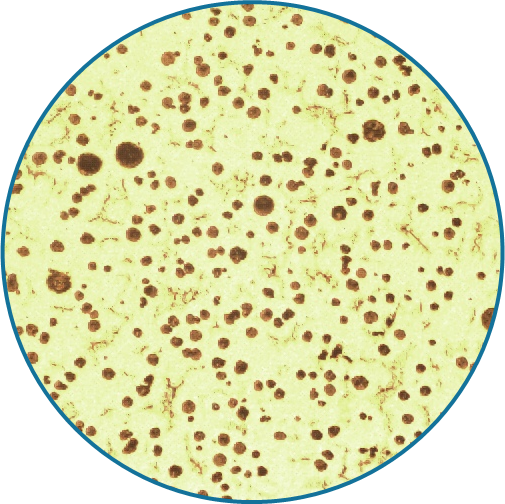

SG Iron

Developed in 1943, it was found that by adding magnesium before pouring caused the graphite to form nodules rather than flakes. This resulted in a new material, with excellent tensile strength and ductility. Adding these mechanical properties of this material to the advantages already offered by cast iron soon led to it finding its way into virtually every mainstream area of engineering. In many cases replacing existing steel castings or forgings due to achievable cost savings.

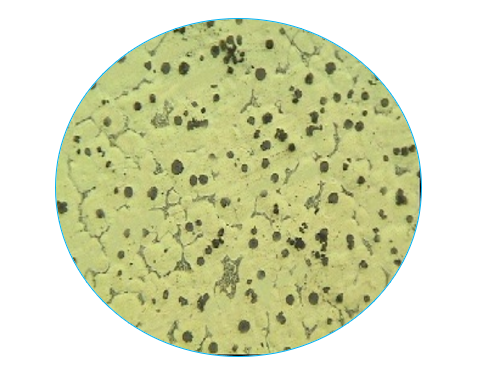

Grey Iron

Grey Iron is the oldest and most common type of iron in existence. It is probably what most people think about when they think about cast iron. It is used in general engineering applications where high strength or ductility is not required. It is however used in applications, which involve sliding surfaces due to its unique bearing properties.

SiMo

The properties of S.G Iron can be modified to give superior heat resistance characteristics by adding up to 5% Silicon and 1.5% Molybdenum. The material is used in turbo housings, manifolds and other cast turbo chrager parts which require high ductility, oxidation resistance, heat resistance, impact resistance and dimensional stability.

Austempered Ductile Iron

Austempering is an isothermal heat treatment process, which significantly improves both the strength and wear resistance of ductile iron whilst retaining the impact resistance and ductility for which the material is noted. A.D.I is a proven cost-effective alternative to cast and forged steel.

Austenitic Cast Iron

By alloying SG iron with Nickel, a stable austenitic nodular iron is produced, giving excellent resistance to growth and oxidation up to 925C. The main application for Ni-Resist is in Gas Turbines and Automotive Exhaust and Turbocharger Systems, where temperature fluctuates between 500 and 1050C. Ni-Resist is suitable in these applications because its ductility, hot strength and low coefficient of thermal expansion provide best resistance to such severe thermal shocks. Physical properties depend on operating temperatures and the exact nickel composition of the SG iron alloy.

Compacted Graphite

Compacted Graphite has excellent thermal conductivity with some ductility and better tensile strength than the family of Grey Cast Irons. Produced by retaining a minimal Mg level (typically 0.01%) after treatment in a low Sulphur base iron. Uses include Diesel Engine blocks ,Clutch plates, Flywheels, Bottle moulds & Ingot moulds.