Quality

Castings Ductile have the following accreditations: ISO 9001, Lloyds Register and American Bureau of Shipping

ISO 14001 is in the process of being implemented (expected approval in early summer 2025), however the business strictly adheres to ISO 14001 best practice with a focus on reducing carbon emissions where possible, including Green Energy consumption, recycling and supplying products for the Renewable Energy markets

Product quality & compliance are key focus areas for our business, be it simple easy to make parts right through to complex geometry, high integrity components used in critical applications. All products offered can be certified by Certificate or Conformity, BS EN 10204 type 3.1 or BS EN 10204 type 3.2

Working with Ductile Castings, you can be assured of market leading standards when it comes to product quality assurance.

Product Conformance

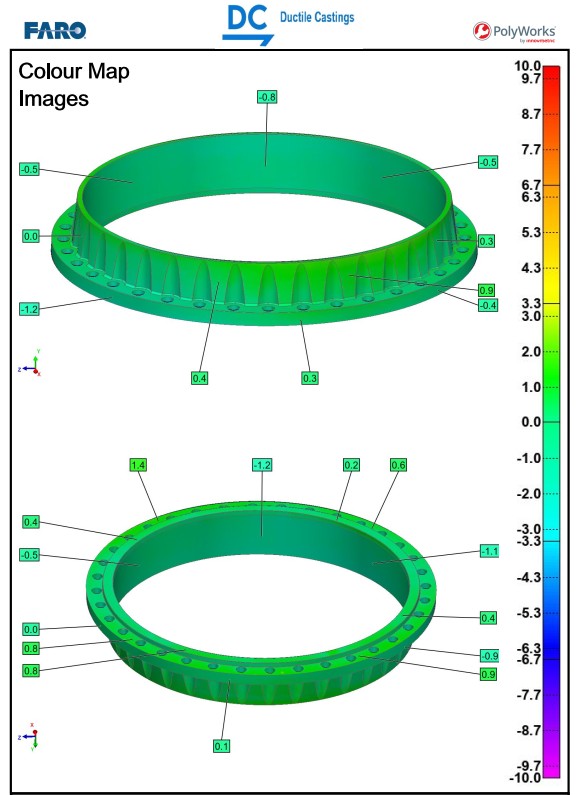

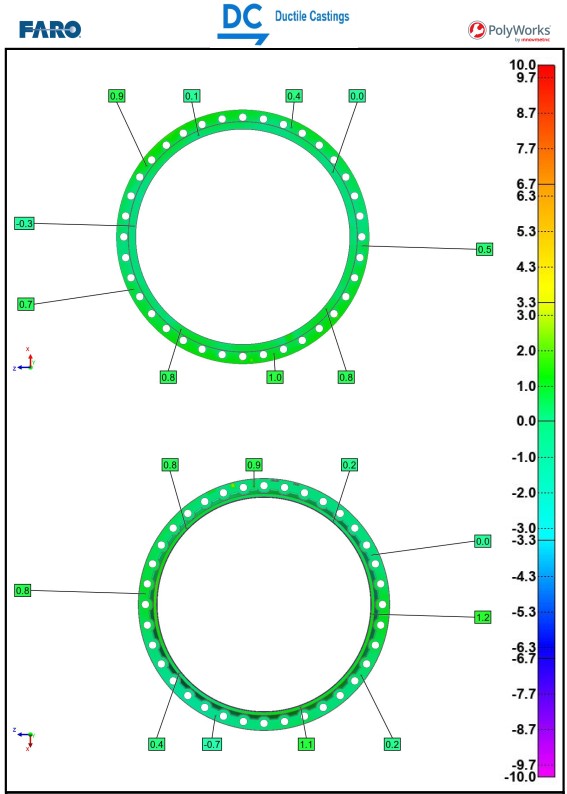

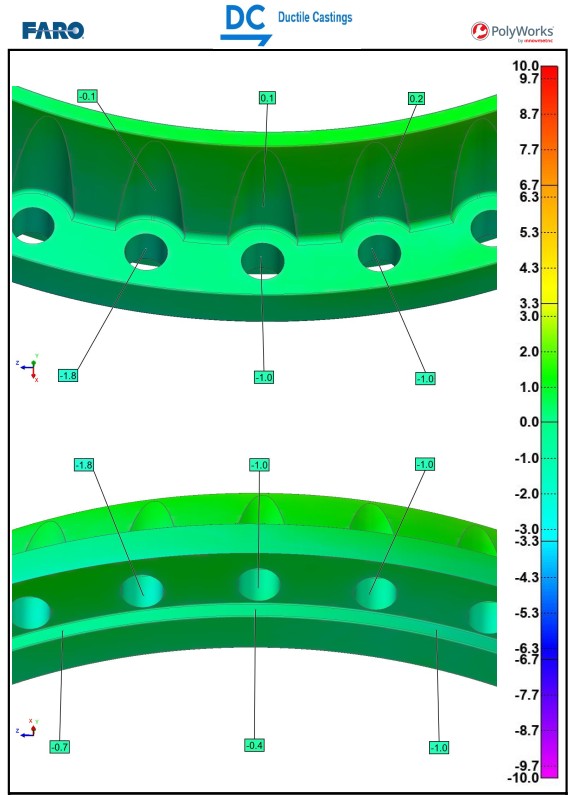

Complete with full in-house NDT Level II capability, covering UT, MPI & LPI, Ductile Castings Quality Assurance team are also proud to support our customers with 3D laser scanning and dimensional control reporting for components. This is offered as part of a product PPAP or customer specific approval process.

Overlaying casting models with actual 3D scan data can identify areas for modification or leaning up, providing you with an assurance that the parts will meet your needs as cost effectively as possible.

Quality Policy Statement

Castings Ductile Limited is committed to providing products and services that fully meet customer requirements and expectations, both stated and implied. Our products fully conform to additional company quality standards and the provisions of applicable regulations and legislation.

As a fundamental part of this policy the company operates a comprehensive quality management system, with structured and documented processes to the requirements of BS EN ISO 9001: 2015 covering all activities defined within the Management System scope.

The elements of Castings Ductile Limited quality policy are:

✔ Providing customers with products which meet or exceed their requirements. The company goal is 100% customer satisfaction, first time, on time, every time.

✔ To provide adequate resources and enhance the knowledge and skills of management and staff

through review and actively pursuing an on-going training policy.

✔ Identifying and acting on risks and opportunities at every stage of our processes ensuring that interested parties needs and expectations are met.

✔ Promoting a culture of continual quality improvements and the principle of getting things right first time, on time, every time.

✔ A philosophy focused on prevention rather than detection with a target of zero defects.

✔ Promoting the quality management system and ensuring implementation is achieved by internal auditing, management review, risk management and corrective action.

✔ Setting SMART objectives in line with the strategy of our business.

✔ Minimising the cost of non-conformance throughout our processes and products.

✔ Every employee is responsible for the quality of their work. As soon as they recognise a quality risk, without being able to remove it immediately, they will report it to their supervisor.

All Company Employees are aware of and committed to the Company’s Quality Policy & Objectives.